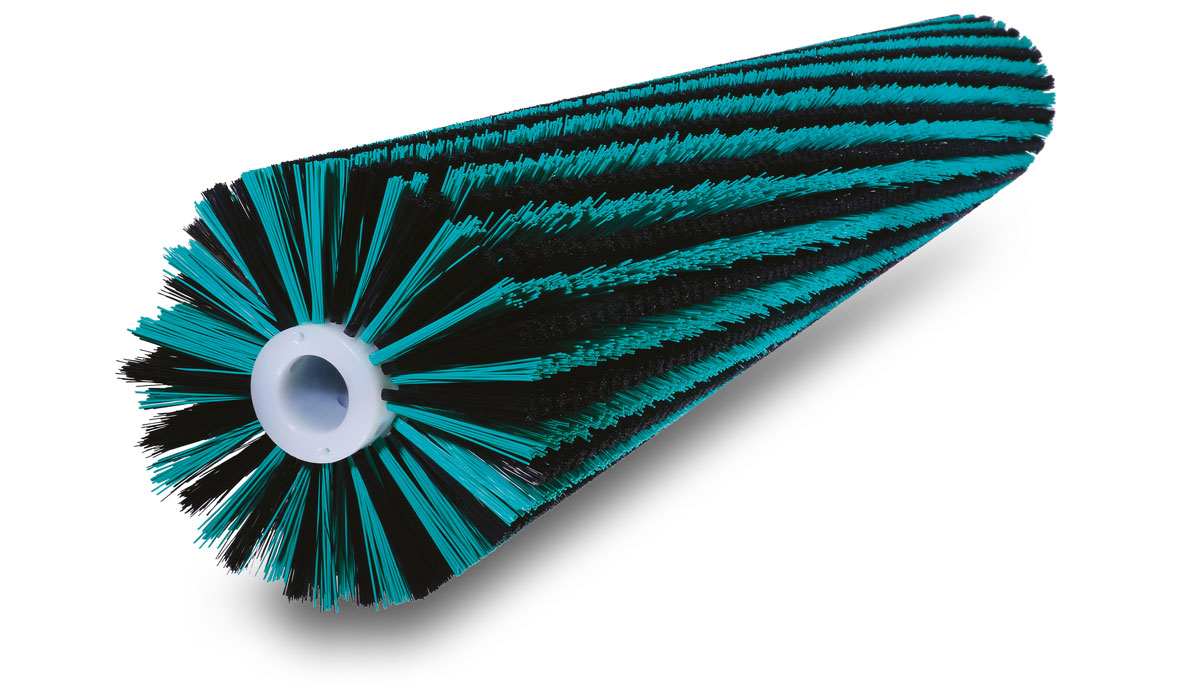

Use of special fibres to avoid scratch marks on sensitive glass surfaces.

Matched fill patterns for optimal cleaning.

Extremely smooth run due to balanced body design and highest production quality.

Lightweight construction.

High mechanical cleaning performance due to strong line load.

On request with integrated, steady shower feed.

Matched fill patterns for optimal cleaning.

Suitable for high speeds.

High self-cleaning effect due to appropriate arrangement of bristles.

(Prevention of surface damage due to dirt particles).

GUTMANN QUALITY for a longer service life, best performance and high economic efficiency.

Zur Ansicht der technischen Daten, bitte Querformat wählen.

Technical data

Overall dimension

Length/Width/Height

≤ 1200 mm / – / –

Diameter

≤ 400 mm

Body

Diameter

≤ 250 mm

Wall thickness

6 - 20 mm

Material

Solid rods, hollow rods or injection-moulded bodies made of all common thermoplastics, such as PP polypropylenes, PE polyethylenes, PS polystyrenes, ABS acrylonitrile-butadiene-styrene copolymers, PA polyamides, POM polyoxy- methylenes/polyacetals and wood composites

Colours

All basic colours, as well as many common colours, special colours possible

Shower feed

Integrated shower feed possible

Fill

Fill Materials

PP, PA6, PA6.6, PA6.10, PA6.12, PET, PBT, variety of animal hair and bristles as well as plant fibres

Density of brush pattern

Light, medium, dense

Brush pattern

Linear, spiral, single-row, double-row, chevron, W-shaped, double helix, zig-zag, segmented

Properties

Very soft, soft, medium, hard

Colours

All common colours, special colours possible

Connection

Connection

Integrated bearing, external bearing, positive drive, internal drive

Development

We develop the appropriate cleaning tool for your photovoltaic and solar cleaning

You cannot find a suitable cleaning tool for your applications, criteria or machines?

Please contact us. We are looking forward to your challenges.